| mm | 0° | 45° | 60° | -45° | -60° |  |

|

|---|---|---|---|---|---|---|---|

|

360 | 360 | 300 | 360 | 300 | x | x |

|

250* | 180* | 130* | 180* | 130* | x | x |

|

500x350 | 420x300 | 300x200 | 420x260 | 250x280 | 500x220 |

|

|

|

|

|

|---|---|---|---|---|

| 3x400V | 2,0/2,6 | 42/85 | 4780x34x1,1 | 682 |

| Lmin | Lmax | Bmin | Bmax | Hmin | Hmax | V |

|---|---|---|---|---|---|---|

| 2800 | 2800 | 1080 | 1080 | 1470 | 2340 | 812 |

From 1 August 2015 modified parameters: the location of the control panel on a flexible console.

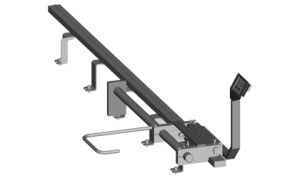

Gravitational band saw machine. Working movement of the arm is caused by the weight of the arm itself, speed is regulated by a choke valve and hydraulic cylinder.

The machine is designed for cutting of material in vertical and angle cuts, angle cuts are possible to set fluently from 0 to 60 grades to the right and from 0 to 60 grades to the left. Change of angle using quick clamping handle.

It is suitable for piece production and small series production. Thanks to its robust construction it enables cutting of wide range of profiles and full materials.

Construction:

- The machine is constructionaly designed in that way, so that it corresponds to extreme exertions in productive conditions.

- The arm of the machine is robust, heavy weldment and it is designed so that a toughtness and a precision of cut was ensured.

- Arm is 2 grades sloped, it increases the lifetime of blade.

- The arm is situated in pretightened slide bushes with a teflon friction surface.

- Down working positions of the arm are controlled by the cam and microswitches. The arm stops automatically after reaching the down position. The arm is lifted by the operator manually.

- The vice is welded. The jaw is made from cast iron. Jaw ensures the safe clamping of the material.

- Jaws of the main vice move in steel leading.

- Moving jaw of the vice is manual with a wheel and trapeze thread. Fixation by the handle with the excenter.

- Basic part of the vice moves according to the direction of the angle cut setting, fixation is made by the handle.

- Turn table is cust iron. Turn table situated on cone roller bearings.

- Manuall turning of the table for angle cuts, the position of the turntable is fixed by the lever with the excenter.The position of the turntable for vertical cutting is arested automatically by the spring mechanism.

- General angles are adjusted by the nonius.

Basic equipment of machine:

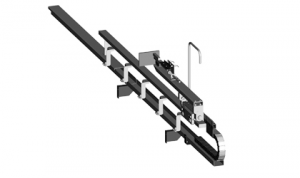

- The blade leading in guides with hardmetal plates and leading bearings and along cast iron pulleys.

- There is a guide situated on the firm beam on the drive side. On the tightening side there is the guide situated on the moving beam.

- The guide beams of moving band guide is adjustable. Manual adjustment and fixing of the guide beams.

- Guide holder moves in adjustabled dovetail groof.

- The saw-band is equipped with a guard, which protects the operator from millings and cutting emulsion.

- Mechanic tightening of the blade.

- Automatic indication of blade tension.

- A cleaning brush for perfect cleaning and function of blade, passive driven by pulley.

- Drive of machine is solved by worm gear box with pernament oil filling. Three phase engine with double winding, two cutting speeds. Termoprotection of engine.

- The cooling system distributes cutting emulsion to the band guides.

- Base with a tank for chips.

- Indication of blade tightening and opening of the cover.

- Controlling 24 V.

- There is a controlling panel ergonomically situated on the flexible consolle. The control panel is equipped with a safety button, which stops the saw. There is also a feed regulator and buttons, which control the various available movements.

Basic equipment of machine:

- Band saw blade.

- Set of spanners for common service.

- Manual instructions in eletronic form (CD).

Operating cycle:

Manually controlled quick clamping vice, cut is regulated by a hydraulic dam per and a restrictor choke valve. operator cutting speed. After finnishing the cut machine will stop itself automatically and an operator lifts the arm manually to the start posittion. Feeding of material is manually.

| Code | Description | Type | |

|---|---|---|---|

| M2V | Engine with the gear box- 2 speed | ST |

| PCK | Cleaning brush of blade, driven passively (driven by pulley). | ST | |

| 360-SRZ-R | Vice behind the cut | OP | |

| 360-RP | Manual upper vice. | OP |

| LIGHT L1 | Lighting of working space. | OP | |

| MINI LUBE | Wasteless lubricating system, instead of emulsion cooling, specially for cutting profiles and non-ferrous metals, neccessary supply of pressed air 6 Atm. | OP | |

| BOX-PCS | Box for cutted pieces with emulsion draining to the waterproof tank. | O | |

| BOX-TRI | Box for the chips with emulsion draining to the waterproof tank. | O | |

| BOX-TAH | Tool for manipulation with BOX-PCS and BOX-TRI. | O | |

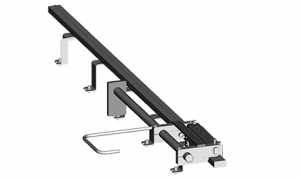

| VD-V-520 | Aditional cylinder, lenght 520 mm. | O | |

| VD-VB-190 | Vertical cylinder 190 mm assamblen od the VD1. | O | |

| VD-BL | Support from vertical side - bearing. Assambled on VD1 | O | |

| RDT 1000/520 | Robust roller conveyor with coolant gutter. Width of cylinders 520 mm, length 1000 mm, 3 rollers, it is possible to put them for RDP or RDZ, load capacity 2100 kg/m. | O | |

| RDT 2000/520 | Robust roller conveyor with coolant gutter. Length 2000 mm, width of cylinders 520 mm, 5 rollers, load capacity 2100 kg/m. | O | |

| RDM 2000/520 | Input or output robust roller conveyor with driven rollers. Driving by electrical engine, worm gearbox and inverter. By chain are driving cylinders. Width of cylinders 520 mm, length 2000 mm, capacity 2100 kg/m. For automatic CNC saws can only be used with SYNC-1 accessories | OP | |

| RDML 2000/520 | Input or output robust roller conveyor with driven rollers. Driving from RDM throught chain. (RDM-L does not work without RDM conveyor). Width of cylinders 520 mm, length 2000 mm, Load capacity 2100 kg/m. | OP | |

| 360-RDP-2000/520 | Input robust connecting conveyor, there is a special shape for angle turning of the machine (it is neccessary for cutting angle - 60°) with a gutter which prevents leakage of emulsion on the floor. Width of cylinders 520 mm, length 2000 mm. | O |

| 360-RDPM-2000/520 | Input robust connecting conveyor with the drive, there is a special shape for angle turning of the machine (it is neccessary for cutting angle - 60°). Electroengine with the worm gearbox drives three firm rollers and it is also the source of energy for RDM-L. Lenght 2000 mm, width 520 mm. | O |

| 360-RDZ-2000/520 | Output robust connecting conveyor, there is a special shape for angle turning of the machine. With a gutter which prevents leakage of emulsion on the floor. Width of cylinders 520 mm, length 2000 mm. | O |

| VD-2000/520/60/6 | Input or output roller conveyor with a coolant gutter. Length 2000 mm, width of cylinders 520 mm, version with 6 cylinders, load capacity 250 kg/m. | O | |

| VD-2000/520/60/10 | Input or output roller conveyor with a coolant gutter. Length 2000 mm, width of cylinders 520 mm, version with 10 cylinders, load capacity 250 kg/m. | O | |

| 360-RDZM-2000/520 | Output robust connecting conveyor with the drive, there is a special shape for angle turning of the machine (it is neccessary for cutting angle + 60°). Electroengine with the worm gearbox drives three firm rollers and it is also the source of energy for RDM-L. Lenght 2000 mm, width 520 mm. | O |

| 360-RB | Side support fixed cylinder, height 200 mm, diameter 67 mm including support - length 520 mm, monted to the convoyer RDT. INPOSIBLE ASSAMBLE ON VD1 ROLLERTABLES. | O | |

| 360-RBS | Side movable cylinder for preparation of bundles, adjustable, height 200 mm, diameter 67 mm it is avalible only with RB. INPOSIBLE ASSAMBLE ON VD1 ROLLERTABLES. | O | |

| 360-RDH | Independent movable cylinder, adjustable height, capacity 700 kg. INPOSIBLE ASSAMBLE ON VD1 ROLLERTABLES. | O | |

| 360 V | Roller of roller table RDT put into gap. | O |

| OZP | Mechanical fixed stop with ruler and scale line 2 meters long. INPOSIBLE ASSAMBLE ON VD1 ROLLERTABLES. | O |

| OZP-D | Mechanical fixed stop with digital display 2 meters long. INPOSIBLE ASSAMBLE ON VD1 ROLLERTABLES. | O |

| OZS | Electromechanical stop working with RDM roller table. It has two contacts. When material switches the first contact, RDM slows down, after switching the second contact, RDM stops. Works only with OZS-L. | O |

| OZS-D | Electromechanical stop working with RDM roller table. It has two contacts. When material switches on the first contact, RDM slows down, after switching on the second contact, RDM stops. | O |

| OZP-L | 2 meters long extension of OZP. | O | |

| OZD-L | 2 meters long extension of OZD. | O | |

| 360-QPARTS | Set of easy worn away spare parts: | O | |

| 360-NAV | Manual instruction – printed version. | O | |

| PAL4 | Packing on the palette 1,5 m x 3,5 m. | O |

Tech. data NO241 are valid on 1.1.2024. Producer has the right to make changes of technical data.

Values contained on this page are only for information purposes. This information is not an offer and is not a public promise. This indicative offer does not give right to close a contract. The only guiding document for the contract is a valid price list.